OUR SETUP

- Design & Development

- Tool Room

- Moulding Facility

- Mould Manufacturing & Assembly

- Testing & Inspection

- Machinery

Product designing from the preliminary concept using sophisticated CAD/CAM and Flow analysis. Emphases will be on reliability, performance, aesthetic value and economy of the individual products.

Product designing from the preliminary concept using sophisticated CAD/CAM and Flow analysis. Emphases will be on reliability, performance, aesthetic value and economy of the individual products.

Packaging design is one of the core segments of our service where art and engineering meet. Dynamism, shelf presence and aesthetic value of the packaging can attract the end user at the retail shelf. Professionally designed packaging can help promote the brand, expand market share and to sustain the competition.

Precision mould manufacturing requires in depth knowledge of the technology in mould designing, selection of tool steel & its treatments and precision machining techniques. As we have the know-how, expertise in moulds and plastic processing, quality of the moulds are ensured to international standards. Operations efficiency, quality management, and technical expertise can ensure highest business expectations.

High quality precision moulds at shortest delivery period are the expectation of the people sourcing moulds. We under stand our customer’s needs and put all our effort to make them satisfied. We are proud to say that our effort in meeting scheduled delivery time, quality of the mould & parts produced from it and service after sales has been rewarded by repeat orders from our esteemed customers. We are specialised in manufacturing of multicavity moulds with inter changeable mould elements. Also we have the expertise and experience in manufacturing of hot runner moulds.

Manufacturing of precision tools require in depth knowledge of the technology in tool designing, selection of tool steel & its treatment, precision machining techniques and workmanship. As we have the know-how, expertise, experience, operations efficiency and skill we ensure the quality, cost and delivery of the tooling to the highest business expectation.

Manufacturing of precision tools require in depth knowledge of the technology in tool designing, selection of tool steel & its treatment, precision machining techniques and workmanship. As we have the know-how, expertise, experience, operations efficiency and skill we ensure the quality, cost and delivery of the tooling to the highest business expectation.

We manufacture following types of custom designed tooling.

- Instrument tube fitting, Instrument valve, Instrument needle valve, Instrument manifold valve, Gas fitting, pipe fitting, moulds, such as Injection, Blow and pressure die casting used by the following segment of the industries.

- Plastic injection and blow moulds for all types of thermo plastics including PET.HDPE and PETG.

Quality Check

Quality Check

- Technical know-how, expertise and experience in tool engineering.

- Equipped design center with CAD/CAM and Flow analysis and manufacturing facility.

- Team of young and qualified engineers, designers and technicians.

- Efficiency in operation and effective quality management system.

- Post production design assistance and service after sales.

- State of the art communication system.

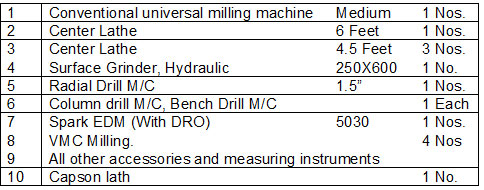

List of Machinery and equipments:

VMC MACHINE DETAILS

1) MANFORD VH 1300 (1300X700X600)

2) MANFORD VH 850 (850X510X500)

3) MANFORD VH 610 (610X450X400)